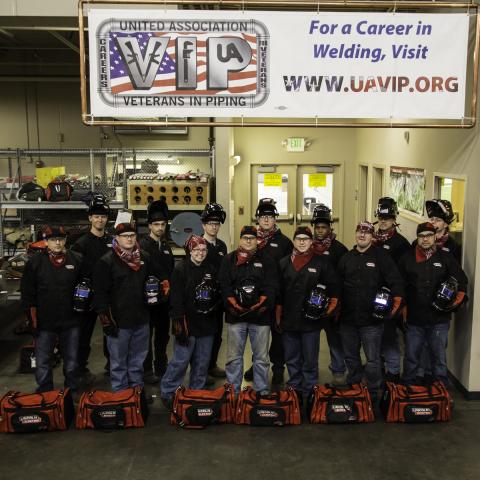

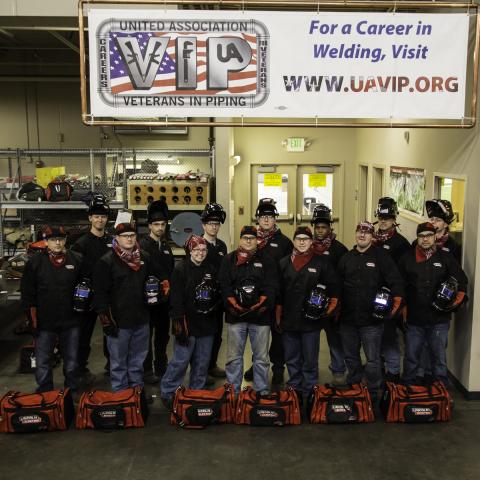

The first Veterans In Piping (VIP) Accelerated Welding Training program for Joint Base Lewis-McChord (JBLM) commenced on January 14, 2013. We are seven weeks into the 18-week program, and training for the 14 active-duty and four National Guard Army participants is well underway. The participants have just recently completed their first major project.

Jay Clevenger, Lead Welding Instructor for the JBLM VIP program, stated, “Picking the candidates for this particular class was no easy task. There were a number of candidates to choose from and a lot to take into consideration for the selection. They came from different backgrounds, had diverse interests and goals, and came from different parts of the country. They had different jobs in the military, but they all had one thing in common—the ability to work together to achieve a common goal, and to work as a team.”

The UA VIP program offers the participants opportunities for lifelong careers as piping professionals. Tess Biesecker, one of the participants, served with the U.S. Army Reserves. She worked as a 25B-IT Specialist with a rank of E-3 and earned a certification as a Level One Modern Army Combatives Instructor.

“I am looking forward to moving closer to family, seeing a new place and meeting new people after graduation,” she stated. “I am also excited about utilizing the skills I’m learning here, and applying the skills I’ll continue to acquire on the job. I am happy that I am becoming a part of the United Association (UA), working my way to journeyworker status. I feel that the UA will enable me to have better benefits, pay and security than many other organizations, which is especially appreciated as I’ll be supporting my husband while he goes to school for the next few years.”

So far the class has learned the rudiments of the proper care and use of applicable tools, critical job safety and health issues, and the fundamentals of oxy-fuel cutting and welding, as well as shielded metal arc welding. In addition, all of the students have completed the OSHA-30 safety program. The participants have received some instruction in basic math skills, pipefitting techniques, and piping and terminology used on the job. They will continue to receive instruction on these subjects throughout the course, along with daily reminders on personal protective equipment and welding and tool safety. The enthusiasm for the class is infectious, and it is evident that all of the participants feel that they made the right choice.

Grant Stanion, a veteran of the U.S. Navy and U.S. Army, who was deployed twice during Desert Storm, including 18 months in Bahrain as an M.P., and endured a six-month WestPac deployment aboard the USS Kansas City as a Machinist Mate in the engine room, is looking forward to a solid welder/pipefitter career to provide for his loving family.

“I think it is an amazing program. I can’t imagine a better-laid-out plan for a veteran about to depart from the military who wants to learn a trade,” he said. “The fact that we are able to do the training while on active-duty significantly reduced the stress associated with job hunting, which would normally be done once the paychecks stopped. The program itself is very detailed and chock full of hands-on experience—this, along with the friendly, highly skilled instructors, makes the whole package a gold mine opportunity.”

Hands-on training is prevalent throughout the program. This includes the proper use of the oxy-fuel equipment, the use and care of the tools involved, and perfecting the skills of the various welding techniques.

Welding Instructor Jay Clevenger added, “They have completed the flat, vertical, horizontal and overhead welding positions on plates with fillet and v-groove joint configurations. They are presently working on welding pipe spools together with the different welding techniques. The students will be provided the opportunity to weld two pipe-spool-weld projects after reaching a certain level of competency with welding pipe spools. The projects will be fabricated in accordance with the pipe spool fabrication drawings that the students are given. The spool pieces are welded in both the vertical and horizontal positions. The second spool piece will be the basis for their final evaluation.”

Adam Rule served four-and-a-half years in the Second Ranger Battalion as a grenadier, rifleman and sniper. He was deployed twice to Operation Iraqi Freedom and twice to Operation Enduring Freedom. He is currently serving in the Washington National Guard as an E-5 Team Leader.

“The hardest part of the first project was welding the smaller fittings on because of the tighter radiuses,” he stated. “It was also difficult to weld the inside of the slip-on flange because of the narrow space where the weld must go. The process of the project was to do a little bit of everything—it contained large and small radiuses, pipe fillet welds and socket welds. It also incorporated reading diagrams and required correct cutting and fitting throughout the project.”

All of the participants agree that the greatest challenge of the program is to consistently produce high-quality welds. They are confident that with their training, time and practice, they will be able to master their instructor’s expectations.

Connor Higgins, who is an active-duty Army E-5 Infantryman, joined the Army in 2008. He was deployed to Afghanistan from 2011 to 2012 and has received numerous awards. He is excited about the program, stating, “The VIP program has exceeded my expectations. It is so amazing to be afforded such an awesome opportunity to be taught the skills I’ll need to transition into an exciting and rewarding career after the military. I’ve learned so much already, and I am looking forward to applying my education to work once I complete the program. I’m happy to participate in the Veterans in Piping program, so that I have a strong base of skill sets when I become a civilian.”

The Veterans In Piping program has taken center stage for the United Association. These dedicated, honorable, brave young men and women are fitting seamlessly into the UA. Specialist Stanley Gates served in the Army for almost four years as a wheeled vehicle mechanic. He was in one of the few field infantry units, the first deployed to Kuwait, which had the high-mobility artillery rocket system (HIMARS). He stated, “While in the military it was very common to work with different groups of people from different parts of the country. I expect my career with the UA will be much the same, as I will go to different jobs and work with different people. I think this transition will be easier because of my military training.”

The participants of the first JBLM Veterans In Piping welding program are well on their way. Seven weeks into the program, and they already have a definitive grasp on the skills sets that are expected from them. With the expert instruction from the UA and the hours and hours of hands-on training, JBLM VIP class 01 is sure to be a success—culminating in the ultimate goal of ensuring lifelong careers for our military heroes.

Comments